APPLICATION RESEARCH & DEVELOPMENT CENTER

Haldia Petrochemicals Ltd operates a Application Research and Development Center in Kolkata with state-of-the-art Analytical & Polymer Processing Laboratory for product development and applications research.

The testing & processing facilities include:

Polyolefin Raw Material

- Melt Rheology

- Density

- Mechanical

- Spectroscopy

- Thermal Characteristics

Finished Products

- Optical

- Mechanical

- Material identification

- Pipe Testing

Polyolefin Processing Facilities

- Twin-screw compounding

- Injection molding

- Blow Molding

- Blown film extrusion

PRODUCT DEVELOPMENT & TECHNICAL SUPPORT

Product Development & Technical Support (PDTS) group operates out of the Application Research & Development Center in Kolkata & has representatives in all the regional offices. PDTS provides support and functions for continuous enhancement of customer satisfaction through quality enhancement of existing products and new polyolefin product development for changing customer needs.

CUSTOMER FOCUS

Product Development & Technical Support plays catalytic roles in developing new customers & markets for HPL products. The activities of PDTS focus on:

- Assisting customers for HPL grade selection

- Extending technical support to customers

- Providing processing guidelines and application related information

- Providing testing and analytical support on raw materials and finished products

- New product development and customization for specific market requirements

- Conformance to statutory requirements for HPL products

- Product positioning, trials and technical establishment

- Optimization of product design based on customer needs

Product Development & Technical Support functions as an interface between customers and the polyolefin manufacturing plants. The PDTS group works in tandem with the customers to understand their technical needs and help them achieve their business objectives with HPL’s products.

APPLIED RESEARCH AND INNOVATION

Since its inception PDTS has contributed to the growth of HPL by introducing, developing and retaining world-class quality products in a competitive market.

PDTS activities in the domain of Applied Research in polyolefins are tuned to serve HPL’s long term polymer business objectives. The research activities are guided by existing manufacturing capacities and challenges in times to come.

The polymer product basket of HPL is a manifestation of the innovative instincts augmented by rigorous evaluations and analytical initiatives of the PDTS team.

The polyolefin products of HPL developed by PDTS:

- HMHDPE film

- HDPE Pipe

- HDPE Blow Molding

- HDPE Injection Molding

- HDPE Raffia & Monofilament

- PP Raffia

- PP Thermoforming

- PP Impact Copolymers for furniture

- PP Impact Copolymers for furniture

- PP Random Copolymer for medical applications

- BOPP & TQPP films

- No-break PP Impact Copolymer grade

- Hi MFI PP Impact Copolymer grades

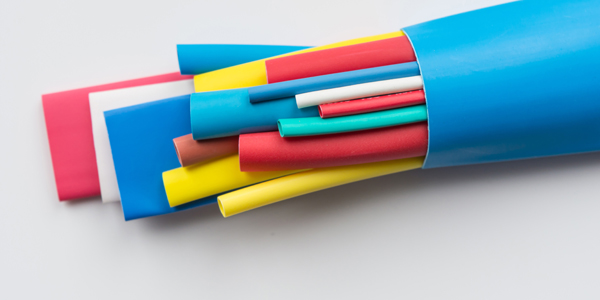

- LLDPE grade for Wire & Cable applications

- LLDPE Drip Lateral Pipe grade

- LLDPE Rotomolding

HPL POLYOLEFIN GRADES FOR THE INDIAN AND THE EXPORTS MARKET

PERFORMANCE ADDITIVES – DEVELOPMENTS AND COLLABORATIONS

PDTS team is responsible for performance additives as part of polyolefin product design. HPL polyolefin grades have been additivated to meet the processing as well as end use requirements of target sectors. These are reviewed and modified to meet the changing market needs of new processing machines and user preferences. PDTS ensures the additivation packages are designed to meet world class product performance.

New generation additives are evaluated to add value to HPL products and provide the same to the customers.

PDTS collaborates with world leaders in additives to build a synergistic relationship that ensures that HPL products retain their edge over competitors. HPL has played key role in evaluating and launching new products from additive suppliers of international repute.

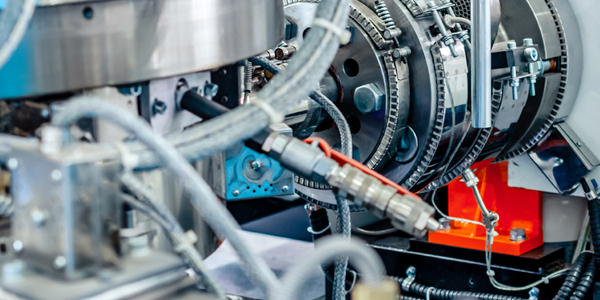

PLASTIC MACHINERY TIE-UPS

PDTS interacts and works closely with plastics processing machinery & mold manufacturers. This exchange is focused towards the application areas and markets where HPL is currently present as well as for future expansion options.

Leading Indian machinery manufacturers design and optimize their machine for throughput and end product quality based on HPL polyolefins. This provides particular advantage to customers adding new processing capacities and with plans to source raw materials from HPL

KNOWLEDGE DISSEMINATION AND TRAINING INITIATIVES

Product Knowledge Programs are arranged by Product Development & Technical Support to disseminate product related information.

PDTS also organizes training programs for the benefit of plastic processing industries in bringing new concepts, exhibition of new products, sharing knowledge of latest technologies, development in plastics processing and applications.

SYSTEMS, MONITORING AND REVIEW

PDTS group has established quality management systems to measure, monitor and control quality and its improvements. The performance of PDTS is continually assessed through SQC tools, external and internal customer surveys, auditing and self assessments.

PDTS plans, performs and monitors its designated activities to conform to the organization’s Integrated Management Systems in line with ISO 9001 standards.

FOR ANY QUERY E-MAIL AT:

[email protected] (For Polypropylene ) | [email protected] (For Polyethylene)